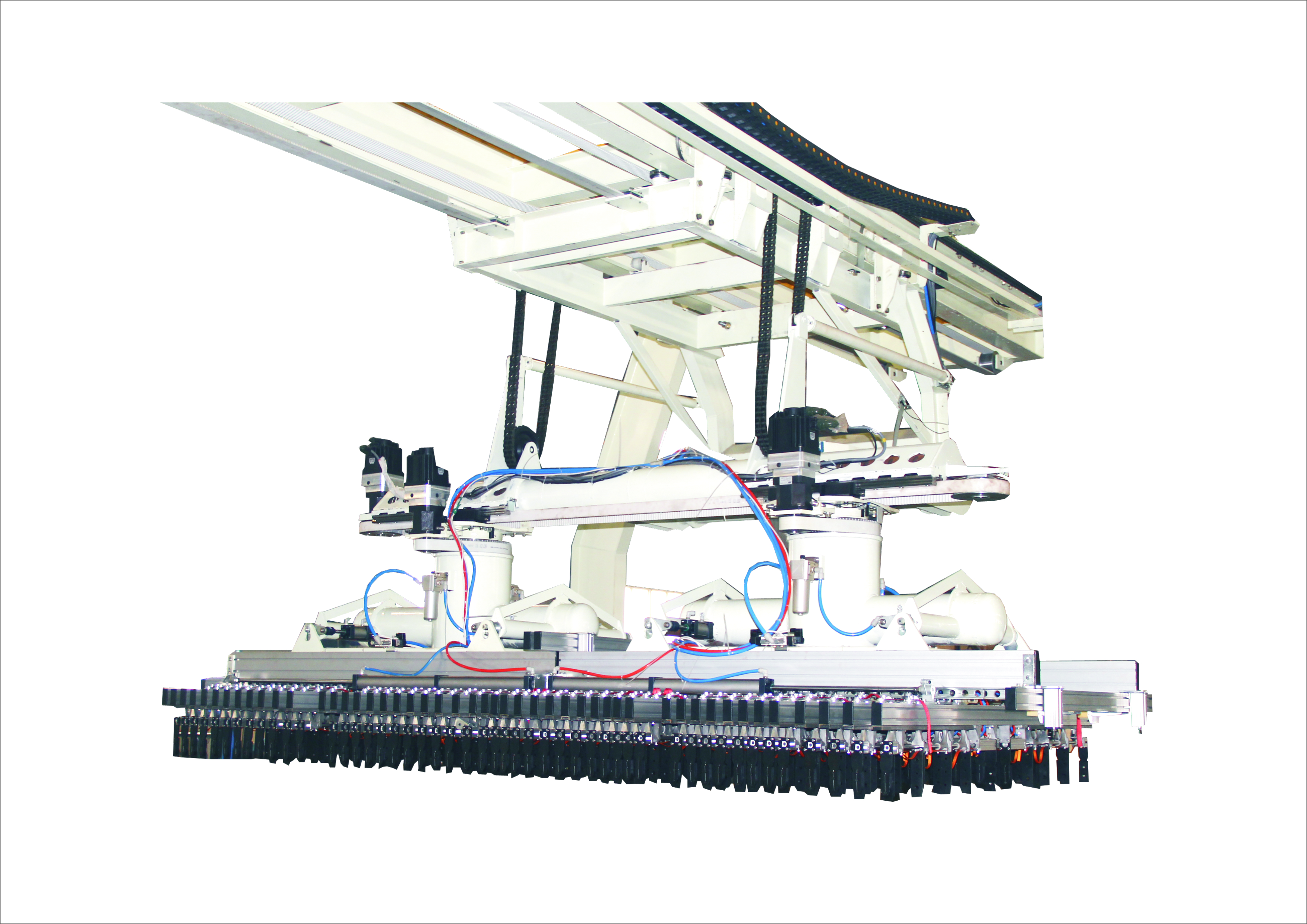

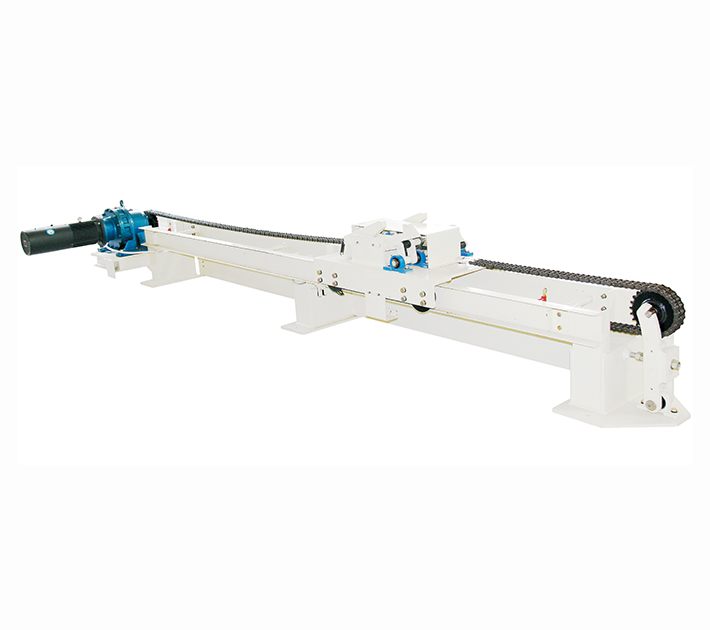

双钢丝架结构,断丝快速转换不停主机,提高生产效率

型号

双丝架型QTB2+QPE1-4(单条)

双丝架型QTB2+QPE5-8(双条)

适合中大型、硬塑半硬塑生产,实现无人或人工操作

规 格

最大切割高度260mm(特别指定)

泥条长度 1750mm-3500mm(可选)

单条型 最大切割频率25次/分钟

双条型 最大切割频率17次/分钟

结构特点

新型一体挂钢丝装置, 调节快捷,减少断丝、断簧;

自动刹车、离合系统,免电机频启,延长使用寿命;

一次推坯、二次推坯模式快速转换;

水平皮带台面气控送坯,减少坯体底部损伤(皮带、辊筒台面可选);

伺服电机作切割动力,达到切条精确、高速平稳、强劲无冲击。

With a double wire frame structure, in case of wire breakage, it can be quickly switched without stopping the brick machine, thus improving production efficiency.

Model:

Double wire frame type QTB2 + QPE1-4 (single strip)

Double wire frame type QTB2 + QPE5-8 (double strips)

Suitable for the production of medium and large-sized brick machines for hard and semi-hard plastic. It can realize unmanned or manual operation.

Specification:

Maximum cutting height: 260mm (specially specified).

Length of mud strip: 1750mm - 3500mm (optional).

Single-strip type: maximum cutting frequency is 25 times per minute.

Double-strip type: maximum cutting frequency is 17 times per minute.

Structural features:

New integrated wire hanging device for quick adjustment and reduced wire breakage and spring breakage.

Automatic braking and clutch system to avoid frequent starting of the motor and extend service life.

Quick conversion between first push and second push modes for unfired bricks.

Pneumatic feeding of horizontal belt tabletop reduces damage to the bottom of the unfired brick body (belt and roller tabletop are optional).

Servo motor is used as cutting power to achieve accurate cutting, high-speed stability, strong performance without impact.